About

JK is one of the leading manufacturers of Biomass Briquettes press. The journey of JK was set off in 1994. Its sole goal was to help the world remain clean and green with its advanced and innovative Briquetting Press Machine Technology.

Welcome to JK Briquettes Press Machine

The leading innovators in Biomass Briquettes press Equipment. Let's turn your waste into energy and make the world a better, greener place together.

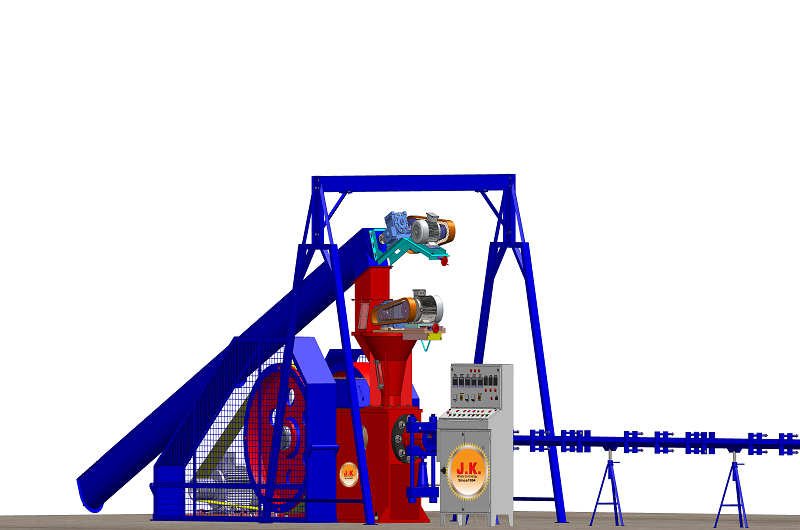

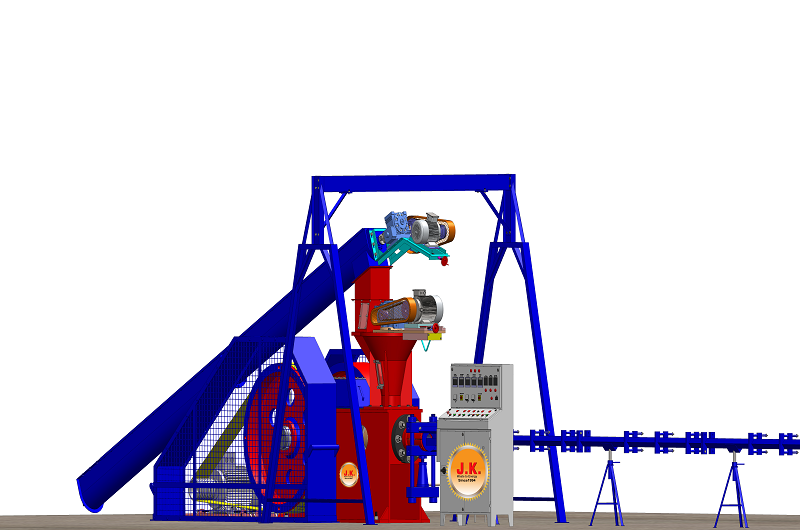

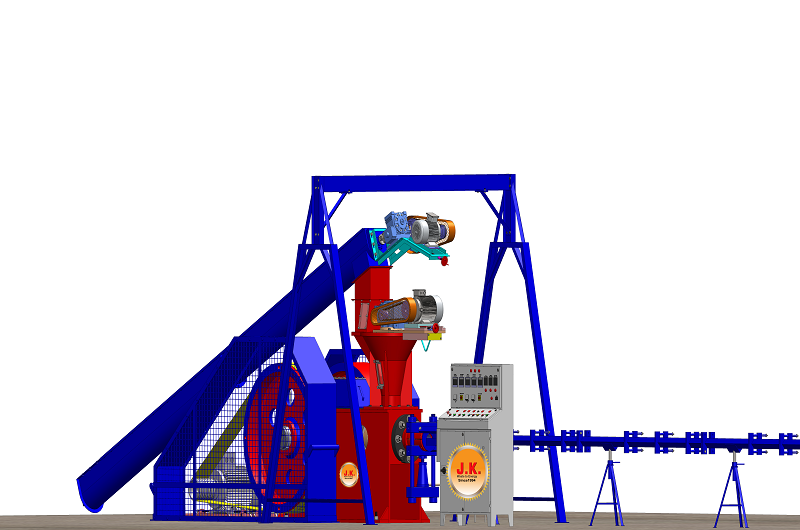

- Since: 1994

- Briquette Size: 65mm/ 75mm/ 90mm

- Material in feed Size: 1mm x 5mm x 12mm

- Material Mositure: 8-12%

- Manufacturer: Briquettes Press

- Power Required: 60HP To 90HP

- Production: 1000Kg To 2500Kg / Hrs

- Feed Material: biomass, timber, forestry, municipal solid, agricatural and many more waste

JK has its manufacturing plant in India where it designs and develops high-quality Briquettes Press. Briquette/Biofuel can be made from all type of Agro waste, Forestry Waste and Municipal Solid Waste. Today, JK is well-known for the Briquette Press Manufacturer, Supplier and Exporter in India and around the world.

Briquette Making Process

All kind of agriculture waste, forestry waste and municipal waste can be converted into briquettes with the help of briquettes press machine, in which there is no need to mix any kind of binder/chemical as it is totally natural process. Just we have to keep size and moisture as require for feeding in briquette press.

Happy Clients worldwide

Projects worldwide

24x7* Support We are always happy to help you

Hard Workers Alwasy Support to customer

Skills

We believe our excellent work in the field of briquetting that making the ... well as fostering creativity at work and inculcating leadership skills, etc.

How to make briquette

Briquette is one of the high demand energy fuel in the world right now. It's a quality fuel which is mostly created from agriculture waste, forestry waste and municipal waste. There is no requirement of any type of chemical to make this fuel which makes it totally eco-friendly.

Wood Chipper Machine

Sawdust Making Machine

Having any type wood waste/logs of more than 20mm size, then it has to be converted in to powder form for best quality output, in which our wood chipper/crusher machine will help you out. There 3 models with different production capacity.

Biomass Dryer System

Wood Sawdust Dryer Machine

Having moisture more than 12% in raw material. Briquettes output quality is not as required. In our biomass dryer system you can convert high moisture raw material into 10-15%. Raw material like agriculture waste, wood powder, municipal solid waste and sawdust can be dried in our agricatural biomass drying system with efficient result.

Briquettes Press

To create this fuel a person requires to install Briquette Press. With the help of Biomasss Briquetting Press Machine you can covert any type of biomass, forestry waste, municipal waste into energy fuel briquettes without mixing any type chemical.

Why Briquettes?

Why Briquettes?

Briquettes know as Bio Coal/White Coal is used as thermal application in many industries. Instead of using fuel like coal & petroleum products which pollutes environment by releasing carbon. It is also easy to store and transport to long distance as it compressed with high pressure.

Benefits of Briquettes

They have a higher practical thermal value and much lower ash content (2-10% compare to 20-40% in coal). In fact, they are 40% more efficient, as well as hotter and longer lasting than Firewood. This greater efficiency can be attributed to their low moisture and density.

Services

Turn your waste into value with our effective briquettes press machine. Discover more about the process of briquetting press here, and contact us for information.

Quality Control

We are an ISO 9001-2015, CE certified and patent & design certified company with many satisfied customers worldwide as we are following EU Standards in our briquettes Press through which we have worked with more than 85+ countries.

Briquettes Project

Briquettes press manage the daily waste which is arise in daily bases and prevent from harm the soil and environment. Briquetting press make the briquette which is easy to handle as it is high bulk density.

Technical Support.

The main service of the Briqquettes Press Project after is after sales service. We have big teachnical team to support our all our client for any assistance 24/7. Customer satisfaction always remain on high priority.

Contact

Regarding briquettes press, briquetting press, biomass drying system and wood powder making machine if you have any query or confusion feel free to call us or mail us. We are always happy to help you.

JKhodiyar Energy

Samrat Industrial Area, Street No.2, Gondal Road, Rajkot, Gujarat, India

Email:

info@jaykhodal.com

Call:

+91 98253 25361